College of Engineering Unit:

This project was started with the goal of mitigating product damages through quality control improvements at Precision Wood Manufacturing (PWM). To do this, the project team compiled PWM’s product quality control checklists (QCC) for their customer and converted them into an electronic format. This electronic QCC added a supplementary quality review process for products that did not pass inspection, giving more visibility to the production manager. Another key addition to this process was photo documentation of the product prior to packaging and when it is packaged. These photos provide a base to dispute some customer claims (e.g. missing hardware).

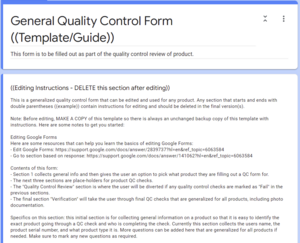

A few weeks into winter term the project had to shift scope due to PWM’s primary customer, Kalon, canceling all of their purchase orders. This meant the original project idea was no longer applicable as was. To account for this change, the team is providing PWM with a generalized quality control form format that can be adapted to new and different products in the future.

Industry Sponsor(s):

Project Communication Piece(s):

| Attachment | Size |

|---|---|

| 599.98 KB |