College of Engineering Unit:

As a society, we need to develop cleaner sources of energy and electricity generation to decrease our dependence on an already dwindling supply of fossil fuels. Hydrogen as an energy carrier has the potential to replace fossil fuels for electricity generation, large-scale energy storage, industrial/residential heating and cooling, and transportation. Hydrogen is also a critical feedstock for many industrial/chemical processes such as in the production of low-carbon metals, ammonia, synthetic fuels, and electronics; food processing; refining/improving oil and biomass fuels; and more.

Currently, the hydrogen generation method with the lowest global warming potential (GWP) is electrolysis, which is the electrochemical splitting of water into hydrogen and oxygen gas. However, as of 2019, nearly 98% of global hydrogen is produced using fossil fuels via steam methane reforming (SMR) and coal gasification as these methods are currently much cheaper than electrolysis. As hydrogen demand grows, many low to zero-emission hydrogen production methods are being studied to determine and improve their environmental, social, and economic viability, but more work is required if hydrogen is to overcome fossil fuel’s commanding grip on the global energy sector.

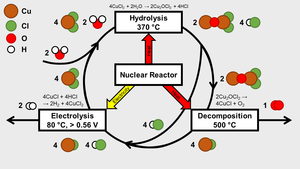

This project’s focus is around one such hydrogen production method: the copper-chlorine thermochemical cycle powered by nuclear waste heat. In this method, nuclear waste heat is used to more efficiently (30-40% compared to wind at 20-40% and solar photovoltaic at 4-6%) split water into hydrogen and oxygen with zero GHG emissions. This project centered around the development of a preliminary design of a nuclear hydrogen production plant with a capacity of 170 metric tons of hydrogen per day via the copper-chlorine (Cu-Cl) thermochemical cycle. To do this, we developed a physically realistic chemical plant simulation using Aspen Plus based on experimental reactor performance from literature. This model was used to calculate critical parameters such as the Cu-Cl cycle efficiency, the required nuclear reactor thermal output, and the flow rates through every key unit operation. We also used the most recent experimental results on the required materials of construction for such a facility, as there are many hazardous conditions, including high temperatures, high pressures, acids, and molten salts, that all must be considered. Using these results, we were able to perform a techno-economic analysis of the plant to demonstrate whether or not it is economically viable. Finally, we developed a process and instrumentation diagram taking into consideration all key hazards and requirements for safe plant operation. This work represents a significant step forward in the development of advanced clean energy technologies, and in the future, nuclear science and engineering students will be able to take our results and design the nuclear power plant that provides the energy required for this Cu-Cl cycle based hydrogen production, completing the preliminary design of such a massive facility.

Project Communication Piece(s):

| Attachment | Size |

|---|---|

| 1012.14 KB |