College of Engineering Unit:

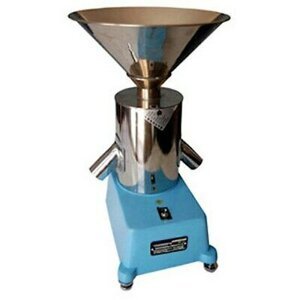

The Oregon State Seed Lab processes over 12,000 samples of seed a year from farms around the region. The inspection process starts with obtaining a 500g sample. This sample represents a small fraction of the total yield and from the 500g, a 5g sample is obtained. The 5g sample is obtained using a gamet seed divider (GSD) through a process called homogenization and seed division. During homogenization the sample is mixed to ensure any impurities within the sample are evenly distributed through the entire sample. During seed division, a Gamet Seed Divider (GSD) is used to “divide down” the 500g sample into smaller sub-samples. A technician is required to reload the sample back into the machine where it is halved,this process continues until the 5g sample is obtained. The current process is labor intensive and can take a technician 10-15min/sample. The goal of this project was to design a system to automate this reloading process by removing the manual labor that is required to reload the seed back into the top of the GSD hopper. To automate the process the team created a system that uses 4 linear actuators to bring the seed from the disposal shoots back up the top hopper. A arm assembly then pours the seeds back back into hopper. The system then navigates back underneath the shoots where the system is turned on and seeds are divided again. This process is repeated until final samples are achieved. The arm assembly rotates using a servo motor and measures the cup contents using a load cell. Once a weight measurement is taken, the system then executes the appropriate line of code based upon the weight value. The system operates using a Arduino logic board and using the button panel, a technician can tell the system which cycle to execute, homogenization or seed division.

Industry Sponsor(s):

Project Communication Piece(s):

| Attachment | Size |

|---|---|

| 1.42 MB |