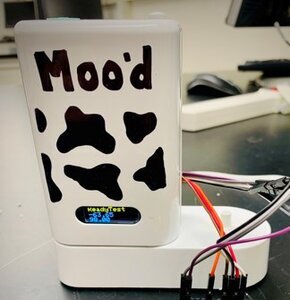

Hundreds of thousands of people in the United States alone seek emergency medical care every year because of allergic reactions. While many people place heavy concern on peanut allergies, Casein allergies are one of the most prevalent, especially in younger children. Casein is a protein present in dairy products that can cause anaphylaxis shock, or the allergic reaction. Symptoms of anaphylaxis include difficulty breathing, restriction of airways, and skin reactions such as rashes. Currently, there are no preventative treatments to anaphylaxis shock. The main methods of treatment like Benadryl and EpiPens are administered after consumption of the allergen and require follow up with a hospital trip. The goal of the Moo’d allergen sensor is to rapidly detect the Casein protein in food products before they are consumed as a preventative testing method. This product is designed to be portable for use on pre-packaged or restaurant foods. The working prototype is comprised of two main components. First, the Casein protein is isolated from a food sample through a series of filters in the designed container. In future development, a buffer solution would be provided to help fine tune the separation process. Next, the device uses UV sensing around 280 nm to detect whether the Casein protein is present or not. In the working prototype, a toothbrush sanitization unit was used due to budget restrictions. Finally, an output is given to the user whether Casein is present or not. For consumer use, the testing equipment would come with controls to check the device is measuring properly before a food sample is measured. Our product is competitive with current testing kits available on the market because it provides a portability that is not seen otherwise. The device allows for testing of samples in a public setting, where most kits require either a large amount of equipment or sending samples back to a lab for processing. Similarly, the device was designed with usability in mind which would lower the overall cost of testing over time.