College of Engineering Unit:

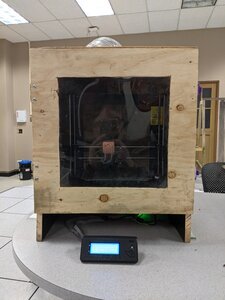

The actively heated 3D printer enclosure’s main purpose is to allow the user to control the ambient temperature around their 3D printer. This is important when using special filaments that have a higher glass transition temperature. Without such an enclosure, when printing, each layer will not be able to effectively adhere to one another causing major print failures over time. Some of the key features built into our enclosure include: server based controllability, an air recycler, and an observation window. Our enclosure is designed to connect to the Mainsail server that our project partner currently has connected to all his 3D printers. By doing this, it allows the user to control both the 3D printer temperatures alongside the ambient temperature of the enclosure. Next, our built in air recycler will recycle the hot air produced by the enclosures heating elements allowing the enclosure to reach even higher ambient temperatures. Lastly, we have included an observation window within the enclosure to allow the user an easy way to monitor their current prints while in operation. One of the main challenges we faced when creating this project, was to create an environment that could maintain an ambient temperature that the user sets. Currently, our enclosure is primarily built from wood; this causes a few issues. The first one being, that pure wood is not a very good insulator leading to a lot of heat dissipation. Second is the fire hazard that is present whenever placing wood near any devices that heat up. In the future, one of the first upgrades that should be done would be to replace the current material for the enclosure with one that would be able to: withstand high temperatures, insulate the ambient temperature within the enclosure from the outside world, and be able to contain a fire in the event one does occur.

Industry Sponsor(s):