College of Engineering Unit:

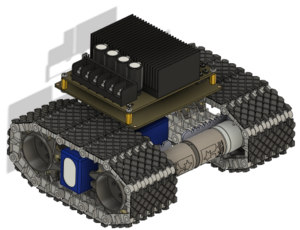

The sumobot is a 3kg robot with a 20cm x 20cm footprint. The sumobot is capable of competing head-to-head in a sumo style wrestling match. The competition match consists of three one-minute rounds. The sumobots attempt to push one another out of a designated arena during each round to determine the winner. Teams are not allowed to provide control or assistance to their sumobots after a round has started. This requires the sumobots to be autonomously driven. Our team used an Arduino Mini controller to achieve autonomy. Our team implemented the engineering process by creating a House of Quality with customer requirements and engineering specifications encompassing the competition rules. Focusing on unique solutions, the process continued with a design matrix, CAD modeling, and computer coding, to manufacture, test, and iterate the sumobot. The budget for the sumobot was $750 provided by the Dalles Area Chamber of Commerce. The final product has four motors, infrared sensors, and track wheels mounted on a 3D printed chassis. The tracks allow for more contact with the surface, more friction, and lower center of gravity. This makes it harder for the competing sumobot to push ours out of the ring. The outer shell is vacuumed formed plastic with ramps on the front and sides with very low ground clearance. The vacuum formed plastic shell is light and durable. This allows weight to be distributed in more desirable places and is still strong enough against hits from the other sumobots. The low ground clearance makes it harder for the other sumobot's to get under our sumobot. The outer shell is covered with infrared absorbing stickers provided by Edmund Optics. The infrared absorbing stickers are a defensive tactic to remain invisible to the other sumobot's infrared sensors. These design decisions created an excellent competitor in a sumobot competition.

Industry Sponsor(s):

Project Communication Piece(s):

| Attachment | Size |

|---|---|

| 374.26 KB |