College of Engineering Unit:

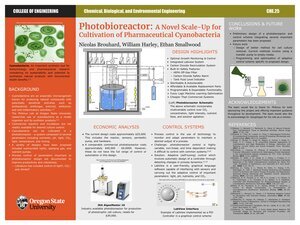

A photobioreactor design to monitor, control and optimize growth conditions for cyanobacteria used in pharmaceutical research. Sensors monitor pH, temperature, carbon dioxide, light intensity, nitrate, and reactor fluid level. Control of nutrients such as acid, base, phosphate, nitrate, and sulfate is achieved through a peristaltic pump. A recirculation system for labeled carbon dioxide significantly reduces operating costs and provides an operator safeguard from oxygen displacement. Safety features include a High Efficiency Particulate Air(HEPA) filter for culture off-gas, carbon dioxide alarm, and reactor overflow interlock. This reactor can be sterilized and autoclaved. Hardware and software integration utilizes LabView software, a graphical and user-friendly programming language. Adaptive control implements fuzzy logic to improve metabolic response algorithm with additional run time. This photobioreactor design at about $25,000 is cheaper and more flexible than commercial systems at $40,000. Parts are also easier to source and replaceable. Functionality in this reactor can be expanded through LabView in the future. This reactor design can culture more diverse microorganisms, at much larger volumes than in comparable reactors.