College of Engineering Unit:

The Low Cost Data Logger is a low cost automotive data collection device designed for Hyster-Yale Materials Handling, inc. The data logger attaches to the diagnostics port of a vehicle and records messages sent through the Controller Area Network (CAN) bus - the machine's internal communication system. The recorded data includes metrics like sensor measurements, error codes, and machine state. Engineers can test vehicles while running the data logger, then download and analyze the data to determine the causes of issues. Such a device allows for rapid identification of vehicle design issues, improving product quality and expediting the testing process.

Hyster-Yale, a forklift company, employs an existing third-party CAN loggers to collect diagnostics on their vehicles. These data loggers cost upward of a thousand dollars per unit, and corresponding software licenses can also cost over a thousand dollars. Hyster-Yale is looking for a more affordable solution with the same capabilities. This project provides an inexpensive alternative, minimizing costs while striving to match the same standard of quality as the existing solution. The new solution is fast, accurate, and reliable. Compared to the existing solution, this design improves on reparability, maintainability, and extensibility.

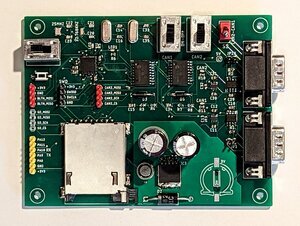

The system is composed of a PCB containing a MCU, two CAN modules, a buck converter, and storage. The system also uses a pre-made Bluetooth module that connects to the PCB via headers. The logger takes in a data packet through a CAN module which sends that packet to the MCU. The MCU then processes the data packet and saves it into storage. The logged data can then be accessed by inspecting the data directly through the SD card or wirelessly via Bluetooth.

In the future, to further improve the CAN logger a uninterrupted power supply can be implemented to the system so that the system can safely unmount the SD card on power loss. Another improvement that could be done to the logger is to implement time stamps and RTC (realtime clock).

Industry Sponsor(s):