College of Engineering Unit:

We produced this project as part of our Senior Design Project for Biological and Ecological Engineering in the College of Agricultural Sciences at Oregon State University.

Breweries produce high-strength byproduct as a result of their operations. Effluent wastewater is acidic, has suspended solids, and is biologically active with fermenting bacteria. Traditionally, this strong byproduct is sent to local municipal processing plants to stabilize and reduce its strength. The main metrics that are important to reduce are BOD and TSS (biological oxygen demand and total suspended solids, respectively). These qualities are difficult to reduce at municipal processing plants because the brewery wastewater causes fluctuations in pH and blooms of bacteria, both of which require resource-intensive corrective action.

The current status quo involves breweries sending their wastewater to a local municipal processing plant, which charges them high fees. In doing this, these breweries miss out on the opportunity to reduce operational costs while also recovering energy from their wastewater. Our project aims to demonstrate how anaerobic digestion can be used to reduce wastewater’s strength prior to brewery discharge to municipal processing plants, while also providing breweries with viable biogas to use in their operations.

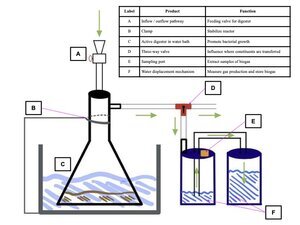

The objective of our project is to employ bacteria to reduce BOD and TSS, while also producing methane that can be reincorporated into the operations of a brewery. We created an anaerobic digester which is a sealed reactor that has a bacterial culture inside of it. The various bacterial strains feed on the high-strength brewery wastewater, hence reducing the BOD (since bacteria are consuming the waning oxygen in the reactor), reducing the TSS (allowing solids to settle to the bottom), and producing methane (via methanogenic bacteria). The digester must reduce BOD and TSS levels to domestic strength levels, which are defined as 300 mg/L for BOD and 350 mg/L for TSS.

This is a bench-scale project, meaning that it isn’t perfectly scalable to operational size. However, this project provides valuable insight on reactor kinetics, bacterial productivity, and the economic viability of assimilating anaerobic digestion into brewery operations. Reactor kinetics show us that bacteria reduce our brewery wastewater to domestic strength levels within seven days. We learned that bacterial productivity is best when reactor conditions are consistent and brewery wastewater is introduced frequently. Anaerobic digestion has a long ROI period of about 6-10 years depending on the scale of operations, but there are breweries nationally and globally that have used this technology for decades and their company continues to augment in size. Despite the high upfront cost, there are environmental, social, and economic benefits to anaerobic digestion.

Project Communication Piece(s):

| Attachment | Size |

|---|---|

| 97.98 KB | |

| 24.61 KB | |

| 358.35 KB |