Fracking, more correctly known as hydraulic fracturing, is a process used to help extract gas or oil from an underground rock formation. A solution called fracking fluid is injected into the ground at high pressure, causing the rock formation to fracture, which releases the entrapped gas. As you can imagine, this process produces a significant quantity of wastewater. A single well can use several million gallons of water, all of which becomes contaminated. Between the year 2000 and 2018, more than 10,000 hydraulic fracturing wells were drilled every year (on average) in the United States, resulting in tens of billions of gallons of fracking wastewater [1].

Currently, most fracking wastewater ends up of in what are called “deep injection disposal wells”. These wells are located near to the fracking site and penetrate all the way through the gas-containing shale layer (deeper into the ground), such that it is geologically isolated from the fracking well. This process has the potential to contaminate groundwater both from leaky systems during the initial injection, as well as long term seepage out of the disposal well. In addition to potential contamination problems, the creation of these wells increases seismic activity in the area, resulting in an increased risk of destructive earthquakes. Interestingly, it is believed that the disposal wells, and not the fracking wells, are responsible for this increase in seismic activity [1].

The motivation for this project comes from the potential to conserve these tens of billions of gallons of fresh water (being used annually), and by doing so, reducing the environmental harm associated with hydraulic fracking industry. We believe it is possible to treat this wastewater for cheaper than it currently costs to dispose of it, and companies will choose to treat the wastewater as opposed to disposing of it. This technology will hopefully reduce the harm caused by the production of non-renewable energy and allow the US energy market to remain robust and competitive while transitioning to renewable energy sources.

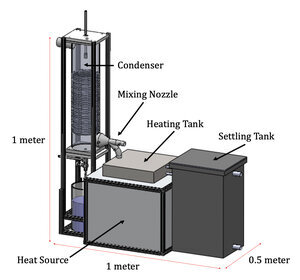

Included as supplemental material for this display is a PowerPoint slide deck. In it you will find both 2D and 3D schematics for the current design of the demo unit, as well as a video of the unit in operation. So far, the work for this project has primarily been testing different components of the system and characterizing how design changes affect the performance of that component. Specifically, we have studied how fouling occurs in both the settling tank and evaporation zone, how heat sources (combustion vs electric) affect evaporation rates, how nozzle geometry changes pressure in the system, and how the ratio of water vapor to cooling water effects condensation rates.

The long-term goal of the project is to create a modular device capable of being mass produced, at a cost comparable to the equipment currently used to dispose wastewater, that can convert fracking wastewater into agricultural-grade water (less than 2.5% contaminants), at a rate of 25 liters per hour, for less than $1 in energy costs per standard barrel. A fracking site can then use as many modular units as necessary based on their wastewater production.

The short-term goal of the project (the completion of the current design with schematic shown in the included PowerPoint) is to create a functional demonstration unit that can convert a sample of actual fracking wastewater into agricultural-grade water (less than 2.5% contaminants). The current design is expected to treat at a rate of about 7 liters per hour and at a cost of less than $2 per barrel.

Please feel free to join our live chat session to ask specific questions you may have between 1:00 and 2:00pm on August 26, 2021.

Works Cited:

- O’Hern, Hannah, et al. “Reducing the Water Intensity of Hydraulic Fracturing: A Review of Treatment Technologies”. Desalination and Water Treatment, May 2021, 121-138.

| Attachment | Size |

|---|---|

| 470.17 KB |