Cryptosporidium is a pathogen that is regulated across the US by the Long-Term 2 Enhanced Rule (LT2 Rule), and additionally by the Oregon Health Authority (OHA) in Portland, where Cryptosporidium is occasionally problematic. To remain in compliance, the city of Portland will begin treating for cryptosporidium city-wide by 2027 with the construction of the Bull Run Treatment Project, costing approximately $820 million. Treating for cryptosporidium is important as it can result in contracting cryptosporidiosis, which can cause symptoms including stomach pain, fever, vomiting and diarrhea. However, traditional chemical treatment cannot inactivate the pathogen, but it is vulnerable to ultraviolet (UV) light which disrupts DNA, RNA, and protein production. As an alternative to expensive future treatment plants, we considered small residential scale UV reactors that hook up directly to consumers’ water supplies. To remain in compliance, the reactors must be capable of deactivating 99.99% (4-log) of all incoming Cryptosporidium oocysts.

The design centered around the following constraints:

❏ Peak flow rate 0.25 kg/s, or 50x the average daily water use for a household of four in Portland.

❏ A 15 watt UV-C lamp with dimensions of 2.54 cm in diameter and 28 cm in height.

❏ Minimum light dose of 25 mJ/cm2 for 99.99% deactivation (based on EPA regulations).

Other assumptions we used for simulating a virtual reactor included:

❏ Reflective reactor internal coating reflects 85% of incident UV rays.

❏ Average degradation in reflectivity of 20% due to hard water.

❏ A small extinction coefficient of UVC based on tap water.

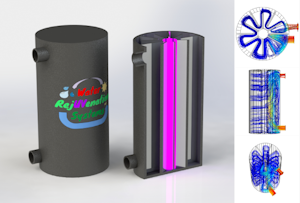

We modelled two reactor designs in COMSOL, and compared efficiency and cost to manufacture. The best design maximized UV dosage and minimized material and fabrication costs. For material of construction, both aluminum and the PVDF (a UV-resistant plastic) are options, as both have approximately the same material and processing cost.

The final design consists of a 13 cm diameter, 25 cm tall reactor with vertical baffles. This gives a long retention time, minimizes channeling, and is easy to manufacture. The following results were found from simulation:

❏ At peak flow, the final design is capable of exposing all Cryptosporidium to a minimum dose of 190 mJ/cm2, well above the EPA requirement.

❏ Due to the reactor’s overperformance, the bulb can be turned on and off according to flow rate, saving energy and extending bulb lifetime.

❏ The reactor can be manufactured using injection molding or casting, and with material costs, manufacturing, installation, and mark up cost at 30% of the unit cost, the final price is about $70.00 to install a unit.

The design team also believes this system could be scaled up or down to fit the needs of larger or smaller scale residences or business. We conclude that for the Portland area that will use the planned water treatment facility to remove Cryptosporidium oocysts, our optimal design could be a cheaper and equally viable option. With the unit price of the reactor, if every resident in the Portland Metropolitan Area (twice the population serviced by the central facility) were to need a unit, the total cost would be approximately $170 million. This leads the conclusion that with more research to further optimize the reactor design and develop scalability techniques, this system could be a better economical investment than the construction of the planned Bull Run water treatment facility. Further research would be required to determine manufacturing costs, installation costs, and costs of reactor design variations.