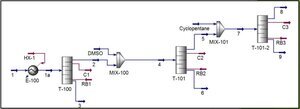

Our engineering team was tasked with a project to design a separation process to increase the purity of a given isopropyl alcohol, IPA, process with a capacity of 250,000 lbs/month, at 99.999 wt% IPA for an industry partner. The incoming feed concentration is 99.651wt% IPA with trace amounts of water, organic compounds, and metals. As stated in the project description, removal of the organics is the main priority for this project. Trace metal reduction of the treated IPA stream is a secondary goal, which was pursued after the removal of organics met project specifications. The overall design of this separation process was modeled in HYSYS and considered economic and environmental aspects.

Initial design focused on continuing work performed in a thesis completed by Rachel Meeuwsen, which centered on designing separation processes for an IPA feed stream with the same specifications. Meeuwsen's completed design produced a theoretical IPA stream at 99.95 wt% by utilizing a molecular sieve for the separation of water, followed by a series of distillation columns. To improve upon these results, the design team performed investigations into alternative configurations and chemical additives used in distillation processes. We investigated three possibilities of separation: distillation columns, membranes, and a combination of the two. The best configuration was decided based on the process’s ability to reach the desired purity, initial capital and operating costs, safety, and environmental impact. Contrasting the work done by Meeuwsen, our team found the most optimized solvents for the job on an economic and environmental basis. In Meeuwsen’s thesis, she determined that the cost of virgin solvents would cost more than the capital invested in the entire plant, meaning recycling of the solvent is integral to increasing profitability of the plant.

Our team reduced capital costs to make this plant as economical as possible by adding recycling systems for these solvents. We also compared the environmental impact of each solvent and took this into consideration. Solvents were chosen based on their performance in separation of organics, their costs, and their environmental impacts. We also researched the removal of metals from the IPA stream to further optimize the semiconductor manufacturing process. The proposed future work stated in Meeuwsen’s thesis was used a guideline for our research. Our goals for completion were to achieve the desired separation of 99.999 wt% with the lowest possible initial capital and operating costs while limiting the process’s environmental impact.