This project is a virtual reality (VR) training tool to be used by workers in modular home factories. Modular homes are houses that are built in a factory and shipped out to a property site. These factories are designed as assembly lines of multiple stations, with each station responsible for different parts of the house–one might build the floor, while another installs the walls. This VR training tool uses a 3D simulation of a real-world modular home factory in order to train workers for individual stations in a realistic environment. Workers are given a set of tasks they must complete at their station and written instructions on how to complete them. The tasks are designed to be the same as the work they will do in a real factory.

By using this tool, a modular home manufacturer can train workers for all of the stations in their factory without losing productivity by halting or slowing down the assembly line. Not only can it be used for new workers, existing workers can train in the virtual environment too. If changes are ever made to the processes at an individual station or the whole factory, all workers that need to adapt to those changes can use the virtual reality simulation to learn to work alongside them.

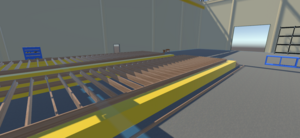

This simulation focuses on a modular home factory’s floor building station. At this station, a worker is tasked with assembling the floor pieces that will be used in the homes. The worker begins by creating the frame with a combination of band boards and rim joists. After the frame is complete, the worker is guided to attach joist hangers along the inside of the rim joists. Once hangers are attached to all of the rim joists, the worker is tasked with laying the joists into the hangers and attaching them. When the floor has been finished successfully, the simulation is complete, and the worker is shown a completion message.

Our project partner is Joseph Louis, an assistant professor of civil and construction engineering at OSU.