Settling Tank and Heating Zone Design in a Fracking Wastewater Recovery System

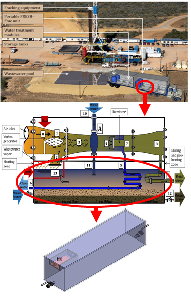

The Freshwater Recovery System for Hydraulic Fracturing or FRESH-Frac system designed by OSU’s WET lab, uses phase change and thermodynamics to achieve irrigation clean water from various fracking wastewater compositions. Fracking wastewater can be difficult to clean due to the contaminants, fouling, portability. Fracking wastewater contains a variety of contaminants with various concentrations of the contaminants because each well is different. The contaminants in the water could cause fouling problems in the purification system which decreases the efficiency. The purification system needs to be portable to reach as many wells as possible and avoid building a stationary plant that can only purify a few wells. The FRESH-Frac system contains several components to purify the wastewater including an air/steam mixing nozzle, a swirl tube demister, a heating zone, and a settling tank. This work will focus on the heating zone and settling tank, both of which were designed to reduce sizing and energy input to the system.

The settling tank was designed to be the first purification section to remove salts and other non-soluble materials such as sand or clay. The settling tank also acts to stabilize the wastewater mixture’s composition for the downstream components by allowing the incoming wastewater stream to mix in the tank to avoid fluctuations in the contaminants. The tank can separate the salts in the water stream by allowing the tank’s water to be concentrated with salts so that all incoming salts will settle to the bottom of the tank and be removed. Removing the salts in the first stage of the system prevents some fouling and conserves energy. The design parameters used to size the settling tank were settling velocity, settling time, specific gravity of contaminants, volumetric flow rates, and the wastewater’s properties. The design methodology was developed from literature.

The heating zone is the second step in the FRESH-Frac system to purify the wastewater. The heating zone adds heat to a portion of the settling tank’s wastewater to evaporate the water and trace amounts of the volatile contaminates such as Benzene and Toluene which will be separated downstream. The vapor from the heating zone will be used to humidify an air stream which will be used to carry the steam to a condenser to collect fresh water. The heating zone is contained to a small portion of the settling tank to conserve input heating energy and control steam flow. The heating zone was designed to sit in the settling tank and pull wastewater from the middle of the tank to be evaporated. The settling tank allows for salts and solid particles to fall to the bottom of the tank to be removed. It also allows for low density compounds to float to the top of the tank to form a floating layer of contaminants. Therefore, the heating zone was designed to pull wastewater from between the settling and floating layers to avoid the most contaminants.

This project presenter is available for live video chat on Sept. 1, 2020 from 1:00 - 2:45 p.m. PDT.