College of Engineering Unit:

What is v2 FlowStride?

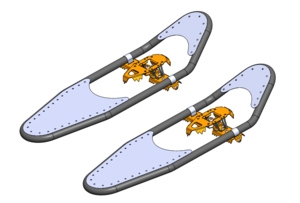

It is a proprietary snowshoe system designed to mitigate strain and improve a user’s performance.

Why v2 FlowStride?

In today’s snowshoeing industry, innovation is stagnant; at least from the standpoint of user performance and the mitigation of strain on the user’s body in uneven terrain. v2 FlowStride solves these issues.

What Contemporary Issues Does v2 FlowStride Address?

In a nutshell, strain mitigation and improved performance.

Project Scope

Maneuverability through the snow using snowshoes has been around for thousands of years. Historically, the solution to traverse through snow has been to increase the surface area of your feet in contact with the snow. Due to the simplistic concept, snowshoe development has been marginal at best, with a few modest innovations here and there to improve user experience. Therefore, this project was focused on pushing the barrier to advance snowshoe technology beyond humble beginnings.

Our sponsor, SUMMIT, innovates within the legacy mountain gear space, bringing new technologies and concepts to market. We will be working in collaboration with our sponsor to rethink and redesign their FlowStride technology: a 2-axes rotational crampon and peripherals. Peripherals include bindings, decking, and frame. Therefore, the scope of this project was to successfully manage the progression and completion of the further development of the FlowStride snowshoe system by optimization of the crampon while maintaining manufacturability, reliability, and delivering a functional prototype. The overarching and historical problem addressed, as was the case with the previous version of the system, was the mitigation of user strain and fatigue during snowshoeing over uneven terrain. To this extent, the previous version has established a baseline platform upon which to further develop and optimize the crampon to the effect of mitigating user strain and improving snowshoe performance.

The specific design challenge and team focus was to optimize the crampon to achieve a functional rotation that is more manufacturable, more reliable, and solves the problems encountered in the previous version of the FlowStride system. Further optimization was pursued in stabilization, attachment, and interfacing. Stabilization in the manner of a set amount of counter force or resistance to rotation in order to simulate the natural articulation of a human ankle. Attachment in the manner of securing the mechanism to the snowshoe frame. And interfacing in the manner of human attachment to the snowshoe.

Finally, the timeline for this project was roughly 6 months and was conducted over the course of two academic terms, Fall 2022 and Winter 2023. Our budget for the project was $1,000, half awarded by the Sports Product Development club (SPD) and a contribution match by our sponsor, SUMMIT. Additionally, our work was split into two phases. The first phase was ideation and conceptualization which was conducted during Fall 2022. The main components of this phase were concept generation, computer-aided design (CAD), and proof of concept through low and high fidelity prototypes. The final phase was design iteration and manufacture and testing. The main components of this phase included request for quotation (RFQ), machining and modifications, finite element analysis (FEA), final assembly, and field testing with corrective modifications. In addition, all reporting and presentation materials were finalized at this time.

Industry Sponsor(s):

| Attachment | Size |

|---|---|

| 2.94 MB |