As the world moves towards renewable energy sources, it is important that we keep up with the ever-increasing demands of energy consumption by our planet. Thermochemical energy storage is a concept that utilizes a reversible reaction to store thermal energy, which can be stored as chemical potential energy. The advantage of using thermochemical energy is that it can store large amounts of energy for an indefinite amount of time. For our project specifically, our objective is to recover waste heat from a power plant and store it for a later time. This is because we want to release the stored energy during the winter months of the year to heat auxiliary buildings in the Carty power plant. To do this, the chemicals are charged and stored in an endothermic reactor. Then the charged chemicals can be used at any time energy is required in an exothermic reactor. Since the chemicals are charged and discharged in a self-contained system, the system by definition is reusable. This means these systems are a one time purchase and can last up to multiple decades. For this project, the solution that we will propose is expected to last up to 50 years without required replacement chemicals. Also, the project has shown that thermochemical energy storage would be beneficial towards saving on the cost of heating the facility.

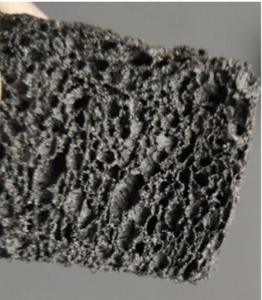

Achievable temperature was the main parameter in choosing which reversible reaction to use as well as toxicity, corrosiveness, and chemical cost. Magnesium sulfates hydration reaction between its kieserite and epsomite hydrates was the best fit for our conditions. In order to prevent the magnesium and sulfate from dissociating in water, we will implant it in a zeolite crystal matrix. This does come at a cost to the energy density of magnesium sulfate which has a high theoretical energy density, and the pellets have about a third the energy density causing a higher storage demand.

The Carty Plant has a large, saturated liquid stream that is around 250°C. Currently, the energy is not being utilized and the stream is being flashed off, and then the liquid water is stored. However, by utilizing the thermal energy within the stream, we can heat a reactor up to a high temperature. This will be the ‘hot’ red reactor, heated by the saturated liquid. The saturated liquid stream after exiting the red endothermic reactor, will still be around 180°C, and then be used to prime an air stream to 85°C for the ‘cool’, blue reactor. The blue reactor contains the exothermic reaction, a reaction that gives off heat. A fan will supply air which will absorb the excess heat, and keep the blue reactor at a steady 85°C. This will heat the air by cooling the blue reactor, which then will heat the PGE building during the winter months. The amount of heated air supplied will be 2000 cubic meters per hour, or 17 gigajoules per hour. Using the low average industrial energy cost for a Kilowatt hour in Oregon the system comes to just over 20,000$ a year, annualized.

If you are interested, you can watch the Youtube video of us explaining our project down below for more clarification.

Thank you for your time and interest in our project. Please come ask us about further details using our zoom link.