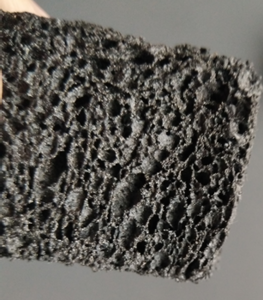

In the United States, industrial demand accounts for ⅓ of total energy use, 25-50% of which turns into waste heat. As fossil fuels continue to dwindle, the need for improving energy efficiency in industrial processes is evident. Portland General Electric’s (PGE) Boardman Power Plant currently has a waste heat stream that is vented to the atmosphere without utilizing any of the valuable energy in the wastewater. This project aims to solve this problem by using a thermochemical energy storage system to preserve this energy. Thermochemical energy storage involves using a reversible chemical reaction to store heat. There are many different categories of thermochemical reactions, but most research has been conducted on solid-gas reactions involving salt hydrates. Thermochemical energy systems have two different steps to them: charging and discharging. For salt hydrates, the charging aspect involves applying a heat source to the hydrated salts to evaporate the water off the salts. The charged salts have now stored that heat, which can be extracted later. The discharging aspect involves adding water to the stored salts, which releases their heat. This project uses a salt hydrate called strontium bromide to store the wastewater heat. Strontium bromide is a perfect salt hydrate for this process as it has a high heat of reaction (798 kJ/kg) and produces heat at a low temperature (~80°C), which is ideal for heating in building applications. However, there are some issues with strontium bromide including poor longevity and corrosion. Our team tackled the issue of longevity by incorporating a 20% graphite composite in our salt pellets to improve their overall lifespan. In order to solve the issue of corrosion, we developed our thermochemical energy systems with Titanium and Hastelloy C as they were corrosion resistant against salts similar to strontium bromide. We developed charging and discharging CAD designs in Autodesk Fusion 360 that could be used for converting the hot wastewater stream into building heating. Our system is capable of producing 200,000 kWh worth of energy during 5 months of charging, which would result in nearly $22,000 in energy savings every year. These promising results demonstrate that thermochemical energy storage can improve the energy efficiency of industrial processes.