One of the most common byproducts of industrial processes is hot water. The heat in that water is energy that, more often than not, gets thrown away. Harnessing that excess energy (despite its low-grade heat) and giving it a new life requires some innovative chemistry and engineering. At low temperatures seen in streams like these, there are limited ways to harness the energy.

The team was commissioned to model thermochemical energy storage heat exchanger systems and review thermochemical reaction set options. The specific energy opportunity they worked to recycle was a continuous stream of 1000 lb/hr saturated steam at 400 psig.

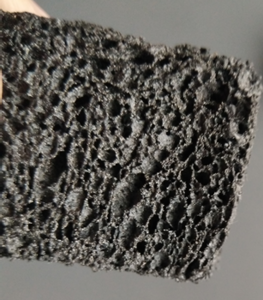

As it is currently most used in industry, thermochemical energy storage consists of an exothermic and reversible solid/gas phase reaction for which products can be easily separated. Salt hydrates are among some of the most common; they use waste heat to dehydrate the salt and add the water back to the dehydrated salt to produce heat energy. Thermochemical energy storage systems vary in storage times, ranging from hours to months, making them useful for smoothing seasonal or diurnal energy consumption cycles. Reaction set options are varied and should be chosen for desired charge and discharge temperature ranges, higher energy density, and easy downstream product separation. Because chosen reaction sets and heat exchanger designs will vary for every situation, the team has worked to create two user-configurable models – a time-dependent solid/gas reaction, and a steady-state liquid/gas reaction.

The two functioning and partially customizable models are for heat-exchanger systems designed to store 80% energy from the 1000 lb/hr feed stream of saturated water. The models were created using COMSOL Multiphysics, and they are designed to account for the complexities of the fluid flow, heat transfer, and reaction kinetics intrinsic to the waste heat energy storage process. COMSOL Multiphysics uses finite element analysis to solve systems of coupled partial differential equations, allowing for the numerical simulation of very complex problems, with complex geometries, and complex couplings.

The finished models give the user a solid starting point for design of a thermochemical energy storage system. Paired with the team’s summary of thermochemical energy storage reaction set options, the user can modify and design a heat exchanger system to meet their needs. The user can choose and specify reaction kinetics, required flows, heat exchanger configuration, etc.