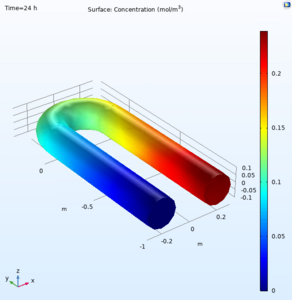

Global warming coupled with the rising energy demands of modern society has yielded an increased emphasis on alternative energy generation and storage methods. Battery technology generally in both conventional and industrial contexts tends to be environmentally taxing in both the production and the disposal of units. That's where Thermochemical Energy Storage Comes in (TCES) as a viable means to address this. It is in principle the process of storing waste heat as chemical potential within reversible equilibrium reactions. These reactions yield products that when combined trigger the reverse reaction instantaneously. In this case the reverse reaction yields the discharge of the inputted heat through an exothermic reaction. TCES stores heat directly as chemical potential within the initial products with a mere 2% loss of energy when converted into the stored state indefinitely for later use. The project team has been tasked with designing a process to harvest waste heat from a power plant to be stored and reutilized at a later time. This will be accomplished through the means of Thermochemical Energy Storage by utilizing a fully reversible endothermic reaction between CuSO4 and NH3 in solid-gas interaction. This process will be modeled in Comsol, Costed, and presented. The final report will also include appropriate operating pressure, process control, and a projection for on-stream availability. Specific choices the team has narrowed down include the decision to proceed with a solid based reaction due to its long term sustainability as well as the selection of an ammonia intrinsic process that allows a higher efficiency. Literature review has yielded a variety of reactant options including MgSO4 a non-Ammonia-related reaction which may be revisited to compare with our final model. Ultimately CuSO4 has been chosen specifically for both its abundance and prevalence in this discipline as well as its favorable theoretical conversion rate. These specific decisions highlighted by Sensible Heat Co. will certainly allow for greater efficacy in waste heat retrieval.