Abbreviated:

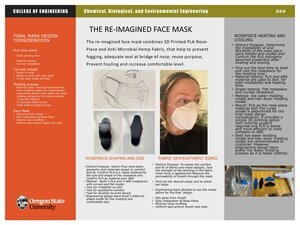

The engineering design team developed a preliminary prototype for a reusable face mask. The design prototype involves the use of a moldable 3D printed nosepiece and antimicrobial hemp fabric. These design features were developed with the goal of preventing glasses from fogging and mask foulage while preventing skin irritation and maximizing comfort.

Student:

For our final design project, our team’s goal was to create a face mask that increases a person’s ability to breath easily without making their glasses fog up. We also wanted the mask to keep the wearer safe during the COVID pandemic. When considering our options, our team also wanted to prevent our mask from becoming smelly from the germs in our breath. To answer these design needs, we created a mask with a 3D printed nose piece that goes inside of the mask. This nose piece can change shape by placing it in hot water so it fits your nose perfectly. We also chose a fabric, called hemp, that does not allow germs to grow. We also found that this fabric was soft and comfortable to wear on the face for many hours.

Summary:

Throughout a 6 month period, September to March, the engineering design team was tasked with developing a novel biomedical device that could sell for a retail price of $200 or less. The team approached this task by developing product concepts relating to a topic that not only interested the group, but also was relevant and desirable. COVID-19 has caused individuals across the globe to seek protective face covering to prevent the spread of airborne respiratory droplets. It has become evident that a reusable and safe alternative to the common surgical mask is needed to protect individuals from respiratory droplets. Current reusable mask alternatives vary in size, shape and materials used. For example, consumers have started using Buff™ or home-made cloth face masks which have unknown protective capabilities and have not experienced intensive protective analysis. In addition, the current alternatives can cause glasses to fog, irritate the face, and cause voices to be muffled and unclear. Our proposed solution addressing the current problems in the market involves a reusable mask design that has a 3D printed nose piece to prevent glasses from fogging and is also made of a material that is breathable, durable and comfortable.

The design team's proposed solution is an antimicrobial hemp cloth face mask with an embeddable 3D printed nose-piece. Antimicrobial hemp offers a sustainable approach to the design and will ensure the highest possible mask strength while also preventing spoilage after multiple uses. The 3D printed polylactic acid (PLA) nose-piece will ensure the mask maintains an adequate seal at the bridge of the nose and prevent glasses from fogging.

Our proposed solution allows for the consumer to generate a customized nose-piece by heating the nose-piece and molding it to the bridge of their nose. Proposed heating methods include submerging in boiling water or using a blow dryer to heat the nose-piece close to the glass point. The user then places the nose-piece to the bridge of their nose to allow for it to perfectly fit the contour of their face.

This solution ensures that the customer will be protected from airborne respiratory droplets while also preventing glasses from fogging, muffled voices, and mask soilage. Further analysis and testing results can be seen throughout the remainder of this report.

| Attachment | Size |

|---|---|

| 3.21 MB |