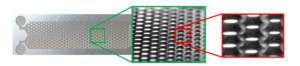

A Multiphase Micro-channel Separation (MMS) unit hosts a liquid-liquid extraction process for the isolation of isopropyl alcohol (IPA) from water at 99.9% purity using a hydrophobic liquid solvent. Solvent selection and solvent recovery system is the culmination of this project.

The separation of an aqueous waste stream containing IPA is complicated by the existence of an azeotrope, limiting a traditional binary distillation to a purity of no more than roughly 87% water. The introduction of a third species to the mixture-- if chosen carefully--will circumvent the azeotropic region, allowing for greater separation of the alcohol and waste stream. Liquid-liquid extraction processes makes use of ternary mixtures, providing a less energy intensive method of separation than traditional distillation. The selection of the third component will determine the efficiency of the separation within the MMS unit, which poses the question the design team intends to answer “what makes a good solvent?”

Ionic liquid solvents (ILS) are a large family of ionic mixtures which are found in a liquid state at temperatures below 100oC and are often such at room temperature. Sometimes referred to as “designer solvents”, properties of these pseudo-species can be tailored for intended use; for this reason, ILS was the focus of solvent consideration. The use of ILS in extraction processes for lower alcohols is a promising but fairly new application with limited literature values available, which restricts the ability to explore ILS candidates for modeling separation within ASPEN. Due to the scale of the MMS device, the separation process is dictated by surface forces and will therefore be prioritized over body forces of the solvent.

Traditional solvent recovery is often accomplished by distillation. This involves exploiting the difference in boiling point of the mixture. By heating the mixed solution to a temperature between the two boiling points only one substance with the lower boiling point will evaporate away, leaving behind the substance with the lower boiling point.

Distillation is a very effective method of separation and has been around for hundreds of years, however it is very energy intensive, which translates to high utility costs for a chemical plant.

One way to attempt to bring down utility costs is to use membrane separation assisted by a vacuum system. Membrane separation uses a physical property of one of the substances to separate them, often charge or molecule size is used to separate species. This process is more specific to the species of chemical used, but much less energy intensive than distillation, where distillation will work with a wide variety of chemical mixtures.