Neutron sources are important in a wide variety of modern applications, ranging from the medical industry, material interactions, and nuclear forensics. The ideal neutron source would produce neutrons at a variety of energies and rates, and produce no neutrons when not in use. Conventional neutron sources rely on the radioactive decay of radioactive isotopes to produce neutrons, which on its own fails to produce a togglable neutronic environment in both the energy domain and the neutron field's strength. An inertial electrostatic confinement (IEC) fusion reactor is an alternative neutron source to radioactive decay, and has many desirable attributes in comparison including field strength togglability dependent on device input voltage, no neutron production when powered off, and the ability to produce high-energy neutrons when fueled with deuterium, a relatively inexpensive substance.

The nuclear fusion neutronic environment is an important regime for study, as the fusion energy industry has seen rapid growth in the past decade including public projects and private industry. The IEC fusion spectrum neutron source (FSNS) proposed here is designed to facilitate research for components and subsystems of the up-and-coming SPARC and subsequent ARC tokamak reactors at MIT. The key need that the FSNS will fulfill is to provide a high (>1,000,000 neutrons/second) neutron source at fusion-relevant energies to irradiate the ARC design’s molten F4Li2Be salt (FLiBe) blanket material, and superconducting REBCO tape to investigate material interactions with the neutron field.

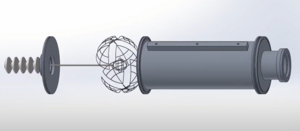

Key subsystems of the FSNS include a high-voltage power supply, vacuum chamber and pump, deuterium fueling system, LabVIEW control, IEC grids, and an IEC high voltage stalk. Modeling of neutronic behavior has been accomplished with an open-source alternative to MCNP: OpenMC. The scope of this project encompassed the full design and modeling of the listed subsystems. The power supply was designed to deliver 45 kV, the OpenMC neutron field model confirmed a safe radiation level at distances where the system operator will be working, and the LabVIEW control system successfully generated a user-friendly GUI to control the device. 3D CAD models of the vacuum chamber, grids, and high-voltage stalk were also created.