A novel solar-driven humidification dehumidification (HDH) desalination technology is developed in the Water and Energy Technologies Laboratory.

Working Principle:

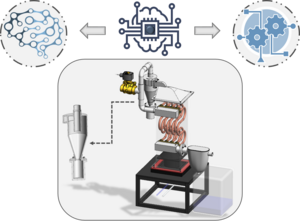

Saline water is atomized with hot air jets actuated by using low grade thermal energy. The spray generated is then evaporated using recouped heat in a first stage heat recovery process. Next, and most importantly, the solid salts are extracted in a cyclone separator. The pure humid air is then dehumidified and the heat released during this process is used to evaporate the spray. The liquid water is thereafter separated from the air in an air/water separator. Finally, the warm freshwater is used to preheat the incoming saline water and then get discharged while the warm air is recirculated in the cycle.

Cyclonic Separation:

Centrifugal separation - the principle of cyclone separators - is widely applied in industrial and chemical processes. Studies in the art, however, did not experiment with humid air of high moisture contents in the solid particles separation tests. This is attributed to the nature of the environments (where cyclone separators are usually used) often deals with dry/ambient air. The high-humidity application also raises other concerns as the high it alters the salt characteristics; high humidities lead to salt agglomerations and promote the adhesion to the cyclone separator inner walls or fouling, should any condensation occur. These factors alter the vortex flow patters inside the cyclone due to the change in solid sizes as well as the modification in surface topography due to the adhesion of salt particles.

Our research, however, has proven that the Cyclone Separator in our process can operate as a self-cleaning device. After few minutes of operation the air stream erode and clean out all the salt depositions and prevent any further fouling once the cyclone walls reach a certain temperature. This amends the desalination industry and water recovery systems significantly. Using Cyclone separators in a HDH process dispenses the need of membranes or packed-beds. It will therefore reduce the energy consumption significantly as it is consumed in pumping brine through the membranes.The cyclone separator allowed the technology to treat water with salt concentrations up to 15% (salt concentration of seawater is 3.5%) into potable water.

Desalination AI-Based Digital Twin:

For a desalination plant, the Digital Twin (DT) will have a large impact on the process as a whole. In addition to the predictive maintenance and risk detection, the digital twin can improve the cycle to another level. Using programmed Artificial Neural Networks (ANN) will allow the DT to mirror the human brain and develop an “intuition” from the data we have. The digital twin will employ very data-efficient optimization algorithms to make use of the minimum number of data points available to obtain high-accuracy results.

AI applications usually requires huge datasets to achieve acceptable accuracy. However, the data-efficient optimization will allow us to train our digital twin based on the minimum number of data points making the process very computationally cheap. It will also automate the process of re-engineering the cycle for different environments and operating conditions. The last use of the digital twin is the ability to predict off-design performance for the cases of cold starts or any unforeseen disturbance.