Produced wastewater is the most significant byproduct of hydraulic fracturing operations and contains numerous chemicals and compounds left over from the fracturing process. In the United States, roughly 98% of the produced wastewater used in hydraulic fracturing operations is deposited in underground injection wells due to the large economic burden of treating this highly contaminated byproduct. There have been several human health and environmental concerns linked to the unintended escape of stored wastewater into drinking water sources. Due to the numerous downsides of storing contaminated water in injection wells, a cheaper and more effective treatment solution is highly desirable.

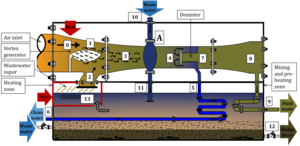

The FRESH-Frac system developed by the researchers at Oregon State University’s (OSU’s) Water and Energy Technology (WET) lab, holds one possible solution. The FRESH-Frac system uses low grade heat to drive simple yet precise distillation process that separates clean water from contaminants. If implemented, this small scale, modular design for a self-contained, scalable water purification unit would reduce the operational costs of treating fracking wastewater in the hopes of incentivizing the hydraulic fracturing industry to move towards a more sustainable future.

In order to achieve the desired performance from the FRESH-Frac system, a robust controller must be applied to the system to maintain essential operation parameters, while not saturating control inputs. Some of the challenges associated with the control of this system are: multiple inputs and outputs to and from the system, unmeasurable disturbances to the system, and finally, highly nonlinear system dynamics due to the many heat transfer and thermodynamic processes at work throughout the system

One class of controllers capable of addressing the previously mentioned challenges are Model Predictive Controllers or MPC. MPC is an ideal candidate for the FRESH-Frac system due to their ability to compensate for unmeasured disturbances, control multiple outputs by modulating multiple inputs, and account for nonlinear system dynamics. These benefits come at the cost that MPC’s are more difficult to design and build than more traditional controller such as Proportional Integral Derivative (PID) controllers.

By paring a MPC with an Artificial Intelligence (AI) neural network, the FRESH-Frac system can be dynamically controlled to optimize the energy consumption, treated water purity, and treated water flow rate. As the first step in the AI assisted MPC strategy, a model of the system will predict the energy, purity, and flow rate for the next n time steps based on the current operation of the system. The energy, flowrate, and purity will be normalized based on the optimal value of each. Next, the normalized deviation for the future time steps will be the inputs to the neural network. The output of the neural network will be an array of weights that the MPC will use to inform its optimization function to ensure all three goals stay within certain bounds and stay as close as possible to the desired value. This is particularly powerful in the field of hydraulic fracturing wastewater as the goals of the system can be changed by the user based on whether they prefer to prioritize or deprioritize one of the system goals (energy, flow rate, or purity) based on the purpose of the treated water. No matter how the priorities of the system change, the neural network will be able to adapt and update the MPC to meet virtually any system requirements.